Laser Peening

페이지 정보

작성자 lvitech 댓글 0건 조회 3,147회 작성일 19-10-24 14:44본문

레이저 핀닝효과

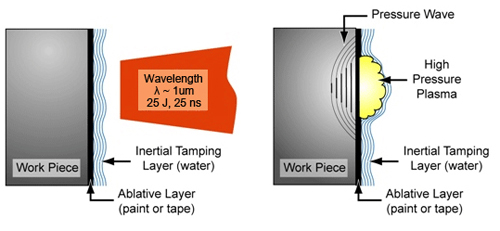

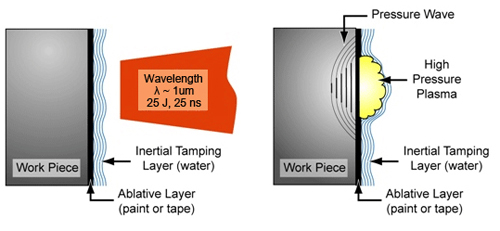

LVI Technologies Inc. Company's laser peening process imparts a layer of beneficial residual compressive stress underneath the surface of metal components to help them better resist the detrimental effects of fatigue and corrosion.

In our laser peening process, a unique high energy laser is fired at the surface of a metal part to generate pressure pulses of one million pounds per square inch, which send shock waves through the part. Multiple firings of the laser in a pre-defined surface pattern will impart a layer of residual compressive stress that is four times deeper than that attainable from conventional peening treatments. Deeper levels of compressive stress provide greater resistance to potential fatigue and corrosion failures

LVI Technologies Inc. Company's laser peening process imparts a layer of beneficial residual compressive stress underneath the surface of metal components to help them better resist the detrimental effects of fatigue and corrosion.

In our laser peening process, a unique high energy laser is fired at the surface of a metal part to generate pressure pulses of one million pounds per square inch, which send shock waves through the part. Multiple firings of the laser in a pre-defined surface pattern will impart a layer of residual compressive stress that is four times deeper than that attainable from conventional peening treatments. Deeper levels of compressive stress provide greater resistance to potential fatigue and corrosion failures

공유자료

RPMC

RPMC Northrop Grumman

Northrop Grumman Synoptics

Synoptics Bright Solutions

Bright Solutions Optoman

Optoman SCANLAB

SCANLAB ASLD

ASLD DPSS Lasers

DPSS Lasers Access Laser

Access Laser Arete

Arete LASERLAB

LASERLAB Holmems

Holmems Prospective

Prospective OminiSensing Photonics

OminiSensing Photonics Beamera

Beamera